Task:

A worldwide leader in producing of construction materials and providing complex solutions in the construction business has asked Geoservice company to optimize its routine processes.

Today the client operates four cement factories and also three quarries of non-metallic extraction. The client’s products are used in infrastructure building, in the manufacturing of a ready-mixed concrete, concrete goods and light concrete products. Every day there are 500 orders of a different kind and quantity being loaded.

Dispatching the delivery process, calculating KPI, reporting on carriers’ indicators all these are a routine and labor-intensive process. Client’s employees have to switch between software programs, to process information manually. These factors influenced the decision to create the united information portal for dispatchers.

The terms of reference were established to solve the problem cases that had been earlier defined.

The problem cases:

- Labor costs for dispatching;

- Human factor in processing information from different sources;

- Lack of a single information space with the necessary information, a manual way of processing information.

The idea:

To create a dispatcher's personal account, which will contain the necessary information about order deliveries, notifications about order status changes, notifications about critical events, generating reports on KPI and timeliness of shipment and delivery of orders. Eliminate manual data processing.

Is it interesting for your business?

Make a request! It's free!

We’re ready to provide such service for your company. Free trial.

How to get car location data? (there are more than 600 of them)

Almost all vehicles involved in the transportation are equipped with GPS / GLONASS devices. No matter what system the carriers have, Geoservice used the Flespi platform to consolidate telemetry and transfer it to the client interface. Calculators for key metrics analyses were also used in Flespi.

The delivery involves both regular carriers, the objects for which are permanently in the monitoring system and transmit telemetry to the portal, and carriers assigned to a one-time order.

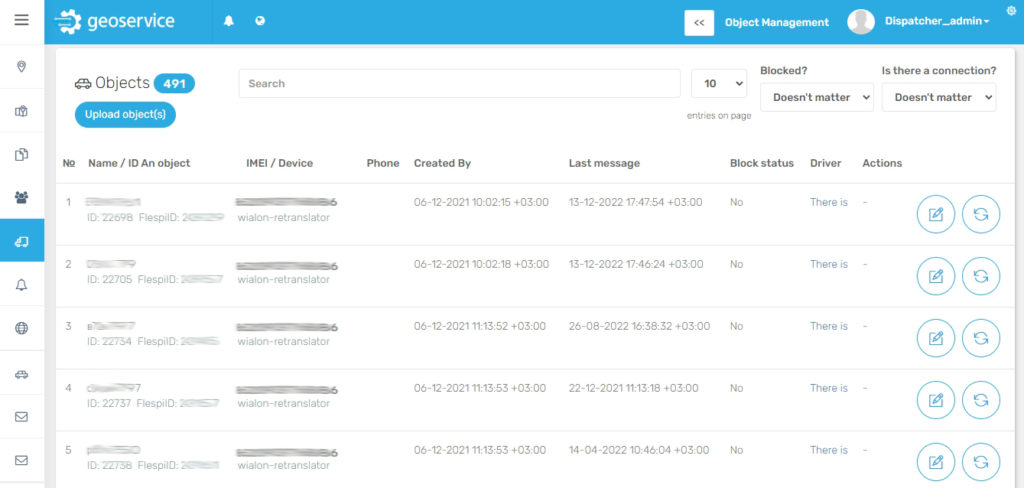

An important point, in some cases a car can be assigned to an order with a short prospect of cooperation, but telemetry for these cars must be in the system. In the dispatcher portal, the file method of creating objects is implemented. An employee uploads an xls file according to the form from the vehicle registration plate and unique ID , the objects are created in Flespi and start receiving relay information from the carrier. The regulation on data transfer is agreed in advance with the carrier. The tool allows you to eliminate duplication when adding objects, objects are stored in a cumulative total in Flespi, but only the objects that are assigned to orders are displayed in the interface.

How to get information about orders?

There are more than 500 orders daily, dispatch from different factories, delivery to dynamic addresses: API integration with the international system that the client is using to administer orders made it possible to obtain data:

- Order number and its status (“planned for shipment”, in the process of loading, in transit, delivered);

- Statuses (time of arrival for loading, time of departure from loading);

- Information about the delivery vehicle and trailer (vehicle registration plate, make of the car, model, color of the vehicle);

- Full name of the driver;

- Information about the shipped volume and the contents of the order (cement brand, etc.).

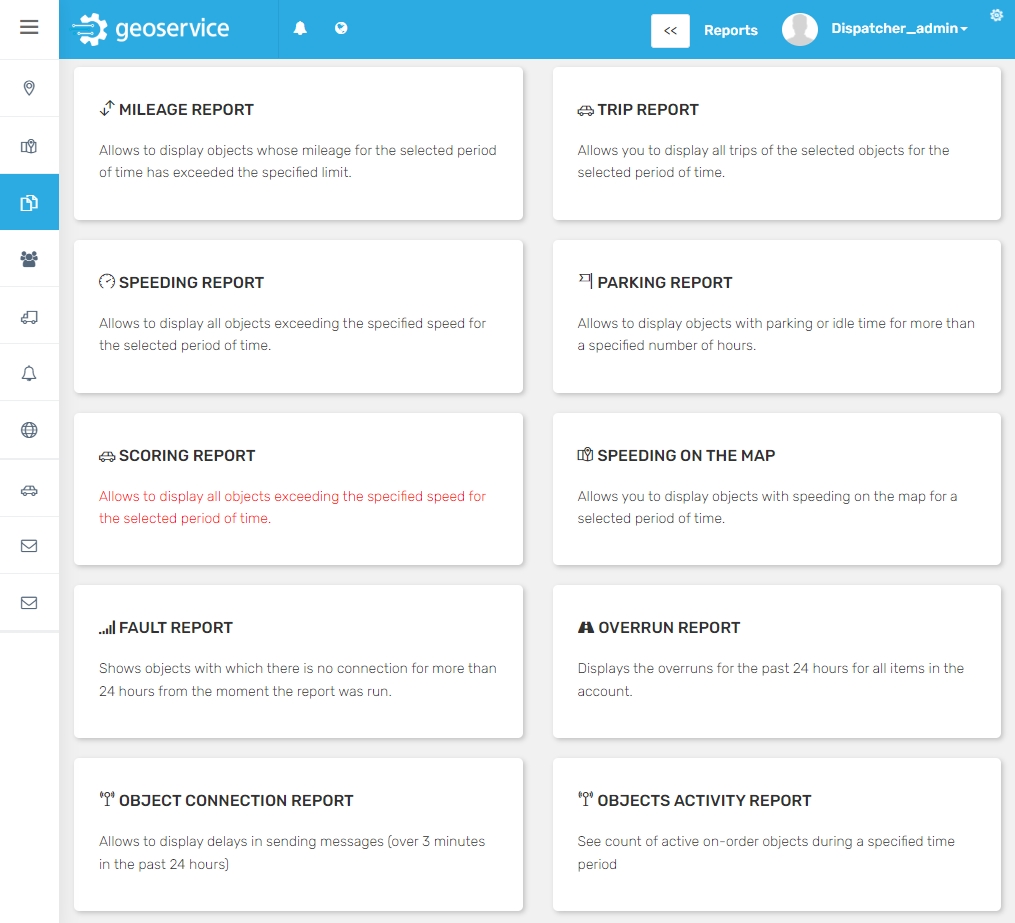

How to get information about driving quality to build a KPI report?

The dispatching portal is integrated with the system for assessing the quality of driving and recording working hours. Based on the obtained data on the quality of driving of each chauffeur of the company, KPI calculation formulas for the company are applied, the information is provided in a single report.

What other reports are available for the dispatcher?

- All requests for each carrier (for each carrier unload all requests with indicated arrivals to and departures from the client),

- Delivery timeliness report (A ratio of the vehicle timely arrival to the specified time),

- Loading timeliness report (A ratio of the vehicle timely arrival for loading to the specified time).

How to combine data in a single interface?

Geoservice24 has a platform of the same name that allows you to make interfaces with the functionality necessary for the final task.

This platform collects telemetry and calculated logic from Flespi, adds information on orders, overlays geoinformation with a choice of map sources, connects traffic jams at customer unloading points.

The Result:

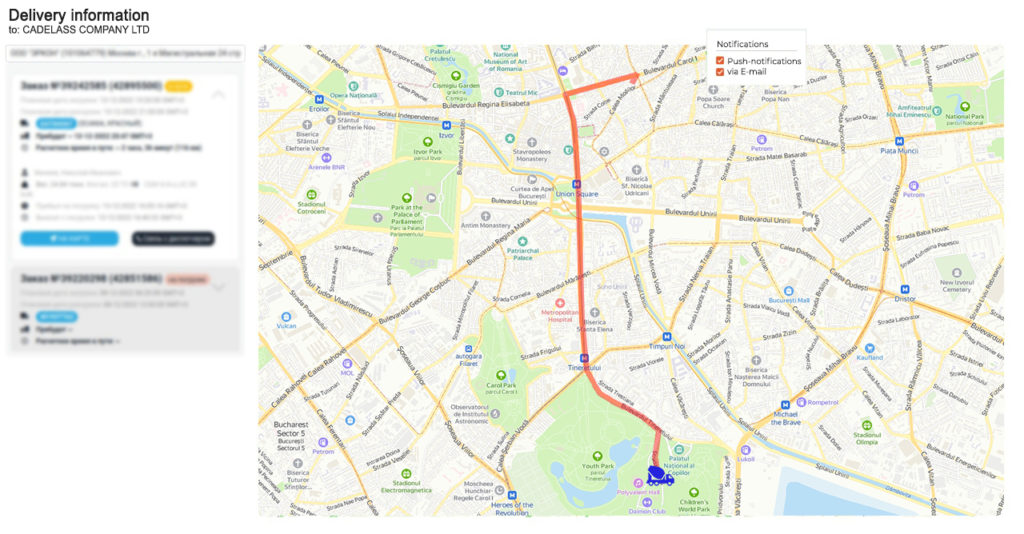

Dispatchers got access to the portal, which allows them to quickly find information on the required order, this is helped by multi-level search filters.

- Order information is available in a compressed and detailed form. The interface displays the history of all orders with a cumulative total;

- System of notifications about changing the status of orders. The order contains a hyperlink to the object on the map. Push notifications about critical events, loss of connection with the monitoring object, violation of the planned download/unload time;

- Reports for the formation of KPI companies on the quality of driving, reports on request and timeliness of loading / unloading;

- A tool to add monitoring objects to the system with daily billing, to count the number of vehicles that have been assigned to orders;

- Car tracking in real time;

- The interface is available in 2 languages.

Is it interesting for your business?

Make a request! It's free!

We’re ready to provide such service for your company. Free trial.